Sustainable Manufacturing: Optimizing 3D Printing for Eco-Friendly Production

In today’s world, the demand for environmentally friendly practices in manufacturing is more critical than ever. As industries face increasing pressure to reduce their carbon footprint and minimize waste, the need for sustainable manufacturing solutions has become paramount. One of the most promising technologies in achieving this goal is 3D printing. Known for its ability to revolutionize production methods, 3D printing is increasingly being optimized to align with sustainable manufacturing practices, offering solutions that promote eco-friendly production.

Table of Contents

What is Sustainable Manufacturing?

Sustainable manufacturing refers to the process of producing goods with minimal environmental impact, reduced resource consumption, and a focus on reducing waste. It integrates energy-efficient processes, eco-friendly materials, and innovative technologies to minimize adverse effects on the environment. The ultimate goal of sustainable manufacturing is to create products that meet current needs without compromising the ability of future generations to meet theirs. By adopting sustainable practices, manufacturers can reduce their carbon footprint, conserve resources, and contribute to a cleaner, greener world.

The Role of 3D Printing in Sustainable Manufacturing

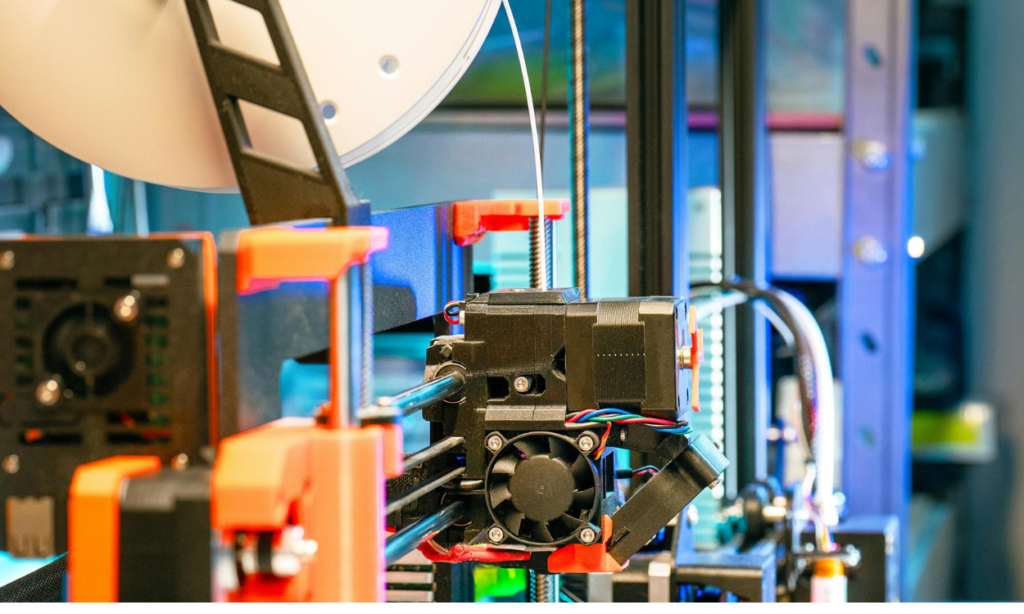

3D printing, or additive manufacturing, is a process that creates three-dimensional objects by layering material based on a digital model. Unlike traditional manufacturing methods, which often involve subtracting material from a larger block (resulting in excess waste), 3D printing uses only the material needed for the product, making it inherently more sustainable. The flexibility of 3D printing allows for the creation of complex designs that were previously impossible to achieve with traditional methods, further promoting resource optimization.

By optimizing 3D printing for sustainable manufacturing, industries can significantly reduce waste, lower energy consumption, and use eco-friendly materials, all while maintaining or even improving the quality of the final product. Here’s how:

1. Waste Reduction

One of the most significant advantages of 3D printing in sustainable manufacturing is its potential to reduce waste. Traditional manufacturing processes often involve cutting away material from a larger block to achieve the desired shape, leading to substantial material waste. In contrast, 3D printing only uses the precise amount of material required for each part. This waste reduction is a major step toward optimizing 3D printing for eco-friendly production.

Furthermore, with advancements in 3D printing technology, the ability to recycle and reuse materials is on the rise. Many 3D printing systems now allow for the use of recycled plastics or biodegradable materials, ensuring that products are not only waste-efficient but also eco-friendly in their production process.

2. Energy Efficiency

Energy consumption is another area where 3D printing can contribute to sustainable manufacturing. Traditional manufacturing methods, such as machining or injection molding, often require high levels of energy to heat, shape, and mold materials. On the other hand, 3D printing typically requires less energy due to its layer-by-layer approach, which is less resource-intensive.

By optimizing 3D printing techniques, manufacturers can further enhance energy efficiency. Advanced 3D printing machines now operate with greater precision and less power consumption, reducing the environmental impact of production processes. Moreover, the ability to print parts on-demand—only when needed—also contributes to energy savings by minimizing the need for large-scale manufacturing operations that consume excess energy.

3. Eco-Friendly Materials

To truly optimize 3D printing for sustainable manufacturing, the choice of materials is crucial. Traditional manufacturing often relies on plastics and metals that are not biodegradable and can contribute to pollution. However, 3D printing opens up opportunities to use eco-friendly materials, such as recycled plastics, plant-based polymers, and biodegradable filaments.

Materials like PLA (polylactic acid) are derived from renewable resources like corn starch or sugarcane and are compostable, offering a more sustainable alternative to conventional plastics. Additionally, as the demand for sustainable manufacturing practices increases, more companies are developing specialized 3D printing materials that are both eco-friendly and high-performance, allowing for efficient production without sacrificing quality.

4. Local Production and Reduced Transportation Emissions

Sustainable manufacturing goes hand-in-hand with the idea of local production. With 3D printing, manufacturers can produce parts and products on-site, eliminating the need for long-distance transportation of goods. By optimizing 3D printing for localized production, the carbon emissions associated with transporting goods across the globe can be significantly reduced.

This local production capability is especially beneficial for industries like automotive, aerospace, and healthcare, where custom parts or small-batch production is often needed. By using 3D printing for on-demand, localized production, manufacturers can streamline their supply chains, reduce transportation costs, and decrease their environmental impact.

5. Customization and Reduced Overproduction

Another key aspect of sustainable manufacturing is reducing overproduction. In traditional manufacturing, large quantities of products are often produced in anticipation of demand. This leads to excess inventory, which can eventually end up as waste if not sold. However, 3D printing allows for on-demand production, meaning that manufacturers only create what is needed, when it is needed.

This ability to produce custom, low-volume parts eliminates the problem of overproduction and minimizes waste. By optimizing 3D printing for sustainable manufacturing, industries can ensure that they are only using the exact materials required for each product, reducing waste while improving efficiency.

6. Circular Economy Integration

Sustainable manufacturing is not just about reducing waste—it’s also about creating a circular economy, where products are reused, repaired, and recycled instead of being discarded. 3D printing supports this concept by enabling easy repair and modification of parts. With traditional manufacturing, replacing broken or outdated parts can be costly and resource-intensive. However, with 3D printing, manufacturers can easily produce replacement parts, extending the life of products and reducing the need for new resources.

Moreover, some 3D printing materials can be recycled and reused to create new parts, further promoting a circular economy. Optimizing 3D printing for eco-friendly production includes integrating these materials into the manufacturing process, reducing the need for virgin resources and minimizing environmental impact.

7. Sustainable Product Design

Designing for sustainability is another critical aspect of sustainable manufacturing. 3D printing enables designers to create lightweight and efficient products that require fewer materials without sacrificing strength or durability. With traditional manufacturing, design constraints often limit the potential for creating products with minimal material usage. However, 3D printing allows for more freedom in design, enabling the creation of optimized structures that use the least amount of material while maintaining product functionality.

By using 3D printing for sustainable product design, manufacturers can create products that are not only eco-friendly but also highly efficient, reducing both material consumption and energy usage in the production process.

Conclusion

Sustainable manufacturing is no longer just a trend; it’s an essential aspect of responsible production. 3D printing plays a pivotal role in optimizing manufacturing processes for eco-friendly production. By reducing waste, improving energy efficiency, using sustainable materials, and enabling localized production, 3D printing is transforming the way we think about manufacturing.

As industries continue to embrace 3D printing and optimize it for sustainable practices, the potential for a greener, more sustainable future becomes even greater. By integrating 3D printing into their production methods, manufacturers can make a lasting impact on both their bottom line and the planet, ensuring that eco-friendly production is not just a possibility, but a reality for the future of manufacturing. Sustainable manufacturing is, indeed, the way forward, and 3D printing is leading the charge.